Getting the most from design-build delivery often depends on the quality of the electrical, mechanical, and general contractors you select. How can owners and developers identify the right design-build partners? Look for the following factors.

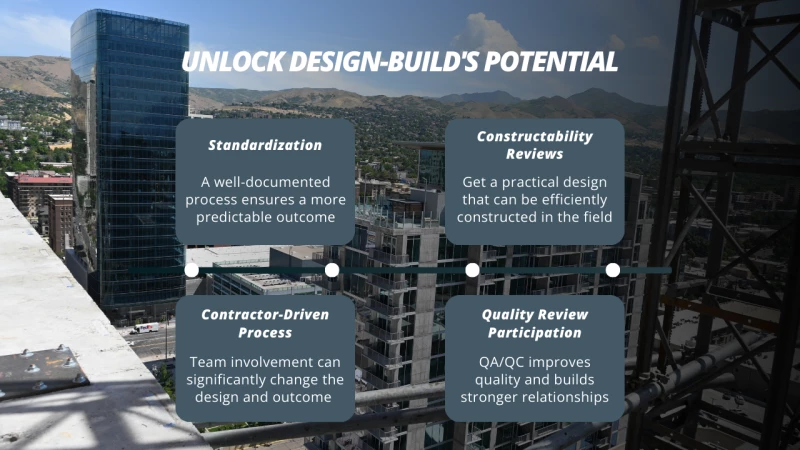

Standardization: A contractor using well-documented processes will ensure a more predictable outcome.

Trends in the AEC industry, such as employee turnover, make standardized processes critical.

Engineers are retiring from the profession in far greater numbers than new engineers are replacing them. This imbalance, coupled with the immense demand for new construction in many markets, puts fewer engineers with less experience under greater pressure to do more work. This same trend applies to the field staff as well.

By standardizing and fully documenting every step of the design process, a design-build partner can support its engineers with detailed documentation that provides clear guidance to help them make the best decisions in every design step. This standardization also keeps engineers on schedule.

Hunt Electric anticipated this challenge to the industry years ago. We responded by extensively analyzing our design-build processes and standardizing them with clear documentation. This empowers us to support new members of the engineering team with the guidance they need to maximize the amount and quality of work they can accomplish with limited direct oversight.

Our standardized and well-documented processes give you and the rest of the team a more predictable and complete electrical design.

Constructability Reviews: Get a practical design that can be efficiently constructed in the field.

Once the design has been completed, a good design-build partner will have a team of expert electricians with extensive field experience review and modify the drawings to ensure they can be built efficiently in the field. The constructability review forces the project team to confront and address potential conflicts with other trades and resolve them in the design phase. This process prevents costly conflicts and rework in the field by making changes when they are the easiest and most cost-effective.

To respond to our clients’ demand for us to bridge the gap between design and construction, Hunt assembled our Virtual Design and Construction (VDC) department. The team is staffed by skilled electricians who use the latest technology to review and enhance design documents. This helps them resolve system clashes, generate detailed drawings to optimize installation efficiency, and significantly reduce the overall project completion time.

A Contractor-Driven Process: When both the owner and other stakeholders actively engage in the initial planning stages, it can greatly influence the quality of your project's design and construction.

Contractors must take ownership of deploying the design-build method and make it easy for the ownership group to engage in the process. Getting the owner's participation early in the project helps the team better understand their expectations and project vision, which will help the team find creative solutions that integrate seamlessly into the design and make the construction process more efficient.

Creating a formal plan with milestones for developers and owners to review and participate in every design stage is critical. The contractor will also perform a page-turn with the ownership group before construction begins to ensure the design is complete and captures their project vision.

Participation in the Quality Review: Involving all members will greatly improve the outcome.

When used correctly, the Quality Assurance/Quality Control (QA/QC) process improves quality and builds stronger relationships between the owner and the design and construction teams.

A fully executed QA/QC plan helps us find opportunities to refine and enhance the electrical design. When owners are involved in the process, they gain a better understanding of the practical details of the project, which eliminates misunderstandings, misaligned expectations, and unpleasant surprises.

Ownership Best Practices to Get the Most from Design-Build Construction Teams

Once you've selected the right partners, here's how you can optimize the design-build process and get the best results.

Get Involved Early – Don't take it for granted that the ownership group and the engineer have identical project visions. Giving input early in the design process allows owners to shape the project to meet their project's unique needs.

Frontload Decision Making – For years it was acceptable to postpone some project decisions after the design was complete and make them in the field. But even decisions as seemingly simple as selecting furniture can cause delays and expensive rework if made after the design is finalized. To ensure a seamless design-build construction process, it's critical to make decisions before the design is complete and stick to them until construction is finished.

Choose a Representative – An owner's leadership team often lacks the time to fully participate in the design-build process. An alternative is to send an employee to the design meetings who share and clearly understands the ownership's vision and can explain it in detail.

How Hunt Can Help

An electrical contractor like Hunt with a long commitment to design-build engineering has experience procuring long-lead equipment early so we can help you avoid some of the delays caused by supply chain issues. And because we hold the warranty on the equipment that we order, we will take the responsibility of ensuring that it is installed correctly and make modifications if they are needed to reduce your risk.

As the industry faces the challenges of fewer engineers who are responsible for meeting greater demand for construction, Hunt will continue to seek new and innovative ways to leverage technology and find the best way to serve our clients. This may include but is not limited to 3D printing, robotics, and artificial intelligence.

Contact us today to learn how we can make design-build engineering work for you.