Bridging the gap between design and construction has always been a challenge to a team's ability to deliver a building that matches the owner's vision and meets their needs. A team equipped with Virtual Design and Construction (VDC) technology can smooth the transition between design and construction and find new opportunities to increase efficiency, accelerate progress, and reduce risk.

Here are examples of how the Hunt Electric Virtual Design and Construction department uses our teams and technology to improve the construction process and do better work for you.

The Power of Building Information Modeling (BIM)

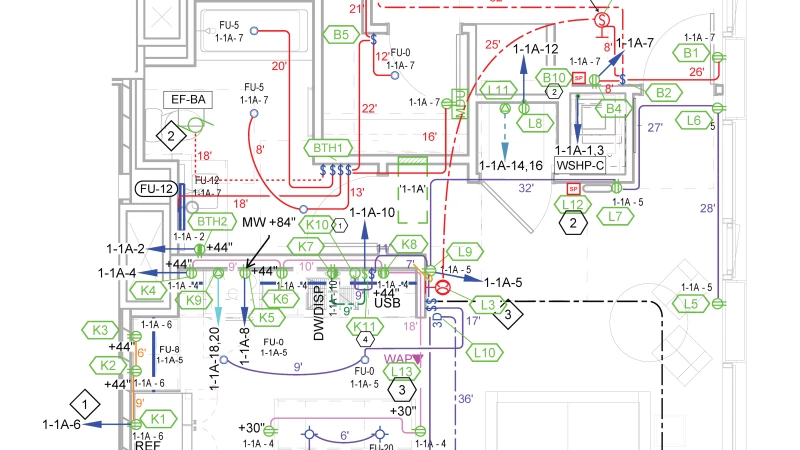

BIM software combines accurate 3D models of a building's mechanical, electrical, plumbing, and structural systems, enabling team members to identify and resolve scope clashes in the design phase.

We used BIM in the early project phase on one of Salt Lake's most outstanding projects, the Astra Tower. This luxury, high-rise apartment complex is more than 400 feet high, 41 stories tall, 680,000 square feet, and includes 377 apartment units. Weekly BIM meetings played a critical role in coordinating this large project. This helped us eliminate clashes before installation began, accelerated the project's pace, and improved work quality.

BIM yielded the same results when building a truck maintenance facility for the E-470 Public Highway Authority in Denver, Colorado. A critical part of keeping the project on schedule was erecting the precast walls in the initial stages. Putting the walls in place early gave us only a brief window of opportunity to install the electrical connections. BIM provided precise coordinates for installation inside the walls. This saved us time and allowed us to keep the project on schedule.

Detailing Excellence and its Role in a Project

A Detailing team transforms initial electrical drawings into meticulously planned project documentation. This includes precise shop drawings and material take-offs aligned with material requirements.

The Back 9 Apartments project in West Valley City, Utah, is a 262-unit apartment complex that benefited from detailing.

The Detailing Team filled in the preliminary drawings with a high level of detail that demonstrated how to run wires in every unit. This augmented information helped installers standardize their process and ensure that work in every unit was consistent and accurate. The detailed drawings enabled electrical installers to deliver on time and keep the project on schedule.

Navigating Precision with the Survey Team

Our survey team harnesses the power of the 3D BIM model to create files and layouts. Then surveyors use GPS technology to pinpoint crucial electrical fixture locations on the jobsite. This precision-driven approach allows project leads to focus on other aspects of the project. These files also serve as a foundation for future as-built drawings.

Our Survey Team converted the Astra Tower BIM model into an electrical layout for each of the 41 floors. The team took information from the BIM software and worked with the field crew to locate the exact points where electrical components would be installed. The Foreman and their team immediately marked the point location and began rough installation. This eliminated the need for manual measurement and allowed us to complete the layout faster and with far greater accuracy.

Prefabrication: A Path to Efficiency

Our Prefabrication department uses data from the BIM and Detailing teams to assemble electrical components in a secure, climate-controlled warehouse delivered directly to the jobsite. This increases quality and saves time.

The Back 9 Apartments benefited from prefabrication when we delivered fully assembled and wired metering banks directly to the jobsite the day they were installed. Prefabrication enabled us to install the metering banks in a fraction of the time it would have taken to assemble them on-site. Just-in-time delivery eliminated the need to store components on the jobsite, protecting them from potential damage or theft.

Prefabrication's phasing schedule allows components to be ordered weeks in advance. It gives project leaders tight control over material management, enabling them to order exactly the components they need and have them delivered on the day of installation.

Transforming Installation Processes with VDC

Our Virtual Design and Construction team eliminates guesswork regarding electrical installation. We use BIM modeling, precise detailing, accurate surveys, and efficient prefabrication to improve every aspect of how your project is planned and delivered.

Ready to take your electrical installations to the next level? Let our Virtual Design and Construction experts transform your projects by eliminating uncertainties and streamlining efficiency. Reach out to us today, and let's discuss how our smart techniques can ensure your projects are completed successfully, on budget, and on schedule.