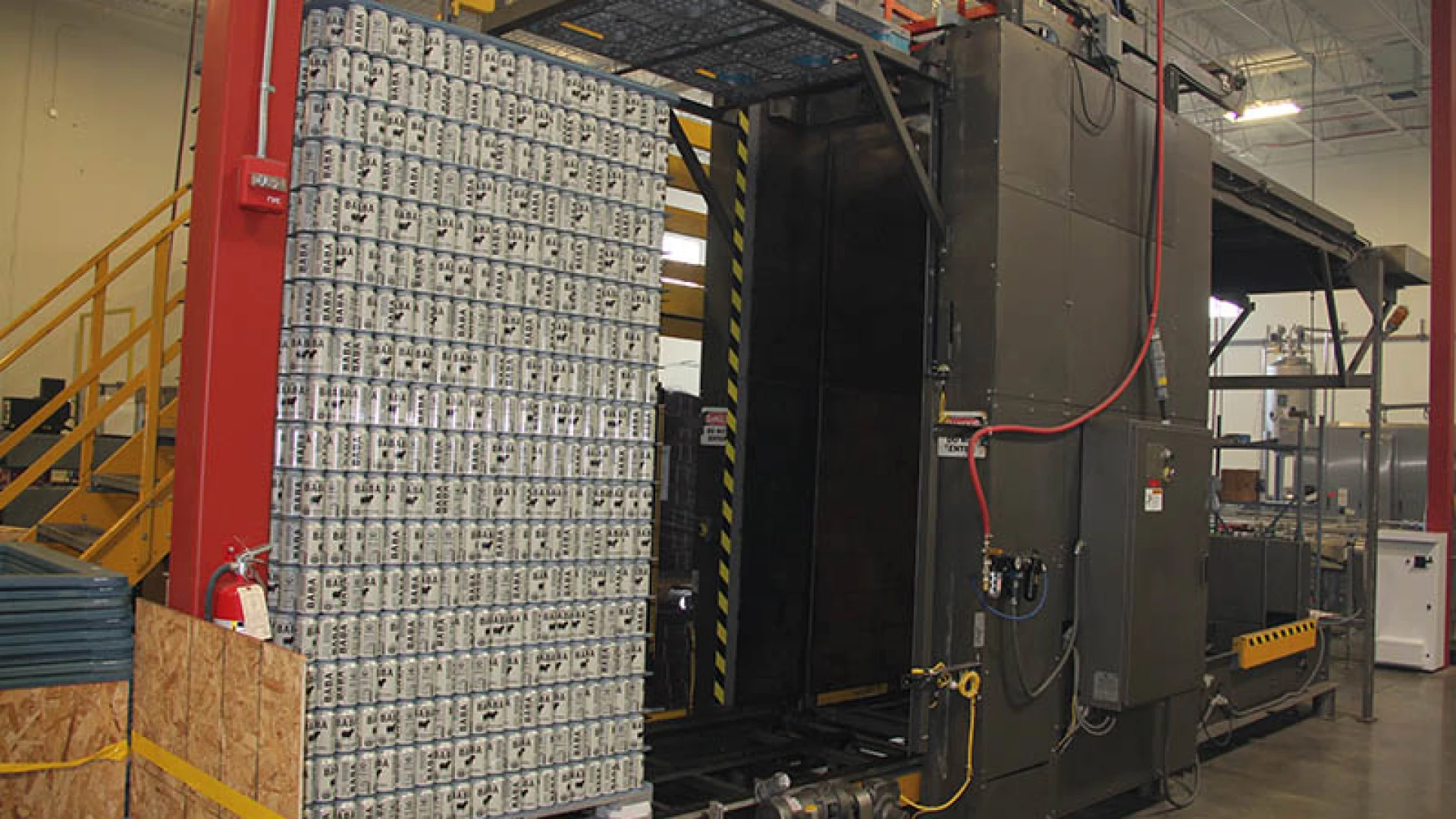

Hunt Electric’s scope of work included the installation of the main service gear and planning and layout of specific equipment power locations. Hunt Electric provided power to the bottling equipment, canning line equipment, conveyor systems, depalletizer centrifuge, batch plant, brew house, auto cleaning system, filtration system, CO2 tank, air compressors room, boilers, 30hp can dryer/ VFD, labeler, auto bottling boxer, glycol cooling system, boilers, keg filler and cleaner, and forklift charging stations. Additionally, Hunt routed and terminated the low voltage control wiring for the proxy sensors, micro switches, conveyor controls, input/output controls for PLC to line devices, solenoids, actuators, photo eye light curtain, PLC communications, and gamma ray fluid detector. Installed the temperature panels and controls for the fermentation and bright tanks. Installed the CO2 tank, boilers, ionized air rinser, glycol cooling system. We also installed and programmed the VFD’s (Mitsubishi, Allen Bradly, Siemens). Provided power and installed controls for the 12,000 sq. ft. walk in cooler which included compressors, fan coil units, automated system, auto slide doors for forklift access and automatic motion systems. Troubleshot and repaired existing VFDs, drive motors, control panels and temperature systems.